In manufacturing, threading is the

process of creating a screw thread. More screw threads are produced each year

than any other machine element. There are many methods of generating threads,

including subtractive methods (many kinds of thread cutting and grinding, as

detailed below); deformative or transformative methods (rolling and forming;

molding and casting); additive methods (such as 3D printing); or combinations

thereof.

1. Casting:

In casting threads are formed by the geometry

of mould cavity in the mould or die. When material freezes in mould, it retains

the shape after mould is removed. Generally low melting point alloy threads are

made by this process; hence they are soft and not durable.

These type of cast threads are used in vending machines, sewing machine,

type writer parts, Plastic moulding is employed for plastics only. This

material may have threads cast in place, but most of the plastics are so easily

worked that tapping will be more economical.

Cast threads in metal parts may be finished by machining, but it

increases cost. Therefore, machining is not used in parts where extra precision

and accuracy is not needed in order to achieve lower cost.

Fig.1 Thread Manufacturing by Casting.

2. Rolling:

Rolling is the most economical and

fastest method of making threads. It is a cold working process whereby a

plastic deformation takes place. No metal is removed and no chips are produced.

Cold rolling strengthens the thread in tension, shear and fatigue because the

fibres are not severed as in other thread making methods, but are elongated and

reformed in continuous lines which increase the strength.

The tools used are generally

expensive, but die life is long and production of accurate threads can be

maintained at high speeds over a long period. Thread rolling can be

accomplished using either flat dies or circular dies.

Fig.2 Thread manufacturing by Rolling

The majority of external threads

produced are made by rolling. Such items as electric light bulb threads, wood

screws, machines and cap screws, gimlet pointed stamped screws, sheet metal

screws, hooks and eyes, as well as many parts are threaded and knurled by this

process.

Flat dies are used in conjunction

with special machines. The top and bottom dies are fixed over top and bottom

slides, which are driven in opposite directions by hydraulic cylinders. The

thread is formed complete within one pass of the blank between the dies. Each

die is grooved with the thread profile, the thread grooves being inclined as

the thread helix angle to avoid interference during rolling. The die length is

such that the blank rotates 4-5 times during one pass. Depending upon the

material properties, the rolling speeds are between 0.50 to 1.25 m/sec.

In the case of circular dies,

these are contained in a die head. Three numbers highly polished thread rolls

are mounted on large, friction free spindles. The thread grooves in the rolls

are not annular, but are true helical grooves.

3.

Chasing:

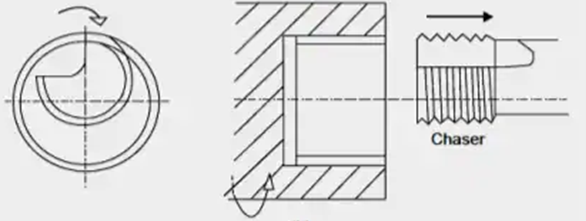

Thread chasing is the process of cutting a thread on a lathe with a

chasing tool which in effect comprises of several single point tools blanked

together in a single tool called a chaser. Fig shows a tangential type chaser

for cutting external thread and circular chaser to cut internal threads. This

is relatively slow method of making a thread.

Tight custom fits can be

made on a lathe, as well as multiple threads, threads on tapers, threads on

diameters not practical to thread with a die, threads that are not standard or

those which are so seldom cut that buying a tap or die would be impracticable,

or threads with a quick lead; all these are well suited for chasing.

Fig.3 Thread manufacturing by Chasing.

This is only method of

producing square threads, as other methods develop interference on the helix.

When a work piece is to be machined in a lathe and also requires threads,

internal or external but concentric with the turning operation, it is more

economical to do the threading in the lathe either by chasing or with a tap or

die.

Chasing lends itself better to non-ferrous materials rather than

ferrous. Multi-start threads can be chased without any indexing of work piece.

Taper threads can be generated by chasing, if chasing attachment is used in

conjunction with taper attachment.

4.

Die-Cutting:

This method is the most widely

used method of producing external threads. Dies are relatively rapid producers

and thus are economical. The quality and accuracy of such thread is only

moderate but is acceptable for most mass-produced articles. For a small shop,

chasing may be less expensive than stocking a complete set of taps and dies.

Threading dies are of

two general types:

(i) Bottom or Round Split Dies and

(ii) Adjustable dies.

(i) Bottom or Round

Split Dies:

These are primarily intended for

hand use but may be used in machines also. These dies are round with a radial

cut closed by a screw which allows them to be adjusted within a narrow range

for a tight or loose fit. These are held and operated by means of a die stock.

Fig.4

Split-die

(ii) Adjustable Dies:

These consist of two pieces which

are held in a collet or mounted directly in a die stock. By a taper arrangement

these may be moved towards or away from the centre so as to provide various

degrees of fit. They are primarily intended for hand use.

5.

Self-Opening Die Heads:

Die boxes are used for high

production of external threads on capstan and turret lathes. Die heads contain

dies or chasers and each is suitable for a given range of sizes.

Three types of die

heads commonly used are:

(i) Radial dies, (ii)

Tangential dies, and (iii) Circular dies as shown in Fig

Fig.5 Die Heads

The dies open automatically when the required length of thread is cut.

When the turret slide movement is arrested by a stop, the front part of the

head continues to move forward by a small amount until the dies spring

outwards, away from the work under the action of a scroll or cam.

Provision is made for taking roughing or finishing cuts by moving a

detent pin to the appropriate position. Since the dies trip open after screwing

operation, the work spindle need not be reversed in order to screw the die head

off again. The dies can be closed by the operator after each screwing

operation, by pushing a handle which partially rotates the front portion of the

head.

Die heads for internal threads are collapsible taps. These withdraw or

collapse inwards when a hardened steel ring around the tap strikes the end face

of the work.

Threading dies are used for cutting or sizing

external screw threads in a single pass. Dies are most widely used for cutting

threads up to 52 mm in diameter.

A solid threading die is in effect a hardened nut with axial openings

forming cutting edges. Normally, dies have from 3 to 6 clearance holes for chip

disposal.

Fig.

6 Threading die

The die thickness is from 8 to 10 turns of the thread. The chamfer

covers from 2 to 3 turns of the thread. The angle 2 j = 40° to 60° is for

cutting through threads and 2j = 90° for cutting threads close to a shoulder.

In standard dies the rake angle is g = 15° to 20°. The relief angle, which is α

= 6° to 8°, is formed on the chamfered (cutting) section only.

6.

Taps:

Available in many types, these are

used for cutting internal threads. There are hand taps and machine taps,

straight shank and bent shank taps regular pipe taps and interrupted thread

pipe taps, solid taps and collapsible taps.

A tap may be compared with a screw

which has teeth formed on it by cutting flutes parallel to its axis, and then

has been hardened so that it will cut metals. Besides forming teeth, the flutes

act as channels to carry away the chips formed by the cutting action.

Hand taps are furnished in three

sets; taper, plug and bottoming. These three are identical in size, length and

vital measurements, differing only in chamfer at the bottom end. The taper tap

has about 10 threads chamfered at the end, the plug tap about 5 and the

bottoming tap only 1. The taper tap allows the tap to be started straight in

the hole easily so as to produce uniform and complete threads.

For threading purposes, these are

used in the order; taper, plug and bottoming. Bottoming tap is best suited when

blind holed threads are required. In cases where threads are to be made by using

only one tap, the plug tap is generally used. Standard taps of sizes 5/32″ to

1/2″ are furnished with four flutes and are used for iron and steel.

These do not provide sufficient

chip room for certain metals that are soft and staringly, such as copper in

which case two or three-fluted taps should be used. Serial hand taps are also

available and are similar to the above set except that each cut only a certain

percentage of the complete thread.

They are numbered 1, 2 and 3, and

are used in that order. These taps find particular use in cutting tough metals

because the load is shared by the three taps, making cutting easier and

producing a smoother thread.

Nut taps are made with straight

shanks (short or long) and bent shanks.

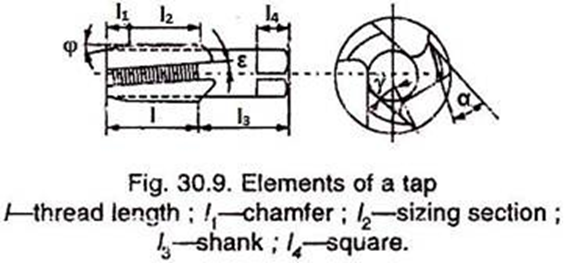

The thread length l of a tap is made up of a chamfer

l1 and a sizing section l2. The chamfer, or cutting

section, has 4 turns of the thread for roughing hand taps, and 1.5 to 2 for

finishing hand taps. Machine taps have from 5 to 6 turns of the thread on the

same section for cutting through holes, and 2 turns for cutting blind holes.

Nut taps come with chamfers having 11 to 12 turns of the thread.

The sizing section l2 of the tap

serves to finish and size the thread being cut and properly guide the tool in

the hole. This portion is slightly back tapered to reduce friction.

The shank l3 is a plain rod with the

square l4 for hand (and sometimes for machine) taps. The

profile of tap flutes has an effect on the cutting process and should

facilitate the removal of chips. Taps with three and five flutes have found

wide use.

The rake angle in taps is g = 5°

to 10° for threading steels, g = 0° to 5° for cast irons, and g = 10° to 25°

for non- ferrous metals and alloys. The relief angle is α = 4° to 12°. Taps are

usually made with straight flutes, but for some applications resort is made to

taps with helical flutes having a helix angle of ε = 8° to 15°, which improves

conditions for chip removal.

7. Milling:

When threads are cut by milling,

the thread is formed by a revolving milling cutter shaped to conform to the

shape of thread desired. Either single or multiple cutters may be used. In the

case of single cutter, all the cutting edges lie in one plane. The multiple

cutters consist of several annular rows of cutting teeth.

A hob may be used for cutting

threads, in which case the teeth lie along a helix. The disadvantage of the hob

type cutter is that it must revolve with a fixed relation to the work, this is

not true of the cutter with annular teeth.

Milled threads may be external or

internal, the only limitation being the size of hole in which a cutter may be

inserted. The threads cut by this method are more accurate than those cut by a

die but not so accurate as those cut with a grinding wheel. A given cutter is

not limited to one size of thread, as in the case with taps and dies.

This method is desirable when the

pitch of the thread is too coarse to be cut with a die. This process is more

efficient than threading on a lathe, especially when the work piece is long or when

large number of stocks are to be removed. Parts such as lead screws are milled

because of the high accuracy and fast production and because the part can

usually be finished in one or two passes.

8. Grinding:

Internal or external threads can

be finish ground by means of a single or multiple edge grinding wheel. The

threads are cut as grinding wheel. A vitrified bond is generally used with a

fine grit of about 60. The process is carried on a special grinding machine

having a master lead screw and gears and means of holding the work.

The wheel rotates at 30 m/sec and

work is rotated slowly. In the case of hardening stock probably grinding is the

only means of forming threads. The accuracy of grinding exceeds that of any

other method and the finish is exceeded only by good thread rolling.

Pitch diameters can be ground to

an accuracy of ± 0.002 mm per 2.5 cm and accuracy of lead may be maintained

within 0.007 mm in 50 cm of thread length. Grinding eliminates tiny cracks due

to hardening and also tearing is always present to some extent in any material

removal method.

Distortions due to heat treatment

may be eliminated by grinding. Parts which would be distorted by milling

threads can be satisfactorily ground. The thread parts which demand high

accuracies and freedom from distortion, and stress cracks are usually made by

this method.

Two variations of

process are:

(i)

Pass over or traverse method and

(ii)

Plunge method.

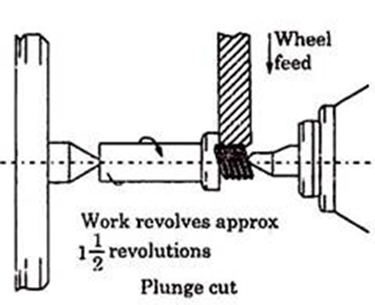

In first method the wheel is

positioned at full thread depth and then the work is traversed past the wheel.

The work table traverse is controlled by a master lead-screw and change gears

are used to suit the thread pitch.

In the case of plunge cut thread grinding, the

wheel is plunged into work to full thread depth. The work piece then makes one

revolution and work traverses one pitch.

Comments

Post a Comment